Bottle Printing Machine

Bulk Enquiry? Call on +91 9667 23456 8

| Brand | Priomia Ventures PVT. LTD. |

|---|---|

| Price of Single | Rs.7499/- |

| Color | Black |

| Power | 1800 W |

| Gross Weight | 7 Kgs |

| Voltage | 220v |

| Print Size | 30oz |

₹15,000.00 Original price was: ₹15,000.00.₹7,499.00Current price is: ₹7,499.00.

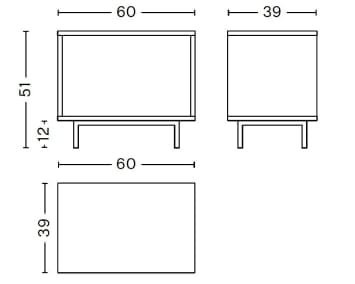

Furniture size guidelines

The compact and well-proportioned silhouette of both the seats and the small sofa, opens up to a new way of using the dining space.

A new, more intimate way of opening up new visual and proportional horizons of the living space, both in homes and in hospitality venues.

The possibility of having both the armchair and the dining and lounge small armchairs.

| Specification | Chair | Armchair | Sofas |

| Height | 37" | 42" | 42" |

| Width | 26.5" | 32.5" | 142" |

| Depth | 19.5" | 22.5" | 24.5" |

| Assembly Required | No | No | Yes |

| Packaging Type | Box | Box | Box |

| Package Weight | 55 lbs. | 64 lbs. | 180 lbs. |

| Packaging Dimensions | 27" x 26" x 39" | 45" x 35" x 24" | 46" x 142" x 25" |

Description

Bottle Printing Machine: Everything You Need to Know

The bottle printing machine is a revolutionary tool designed to create custom designs on bottles, making it a must-have for businesses involved in personalized products or promotional items. Whether you’re printing logos, images, or text on bottles, this machine provides precision, speed, and efficiency. It’s ideal for various industries, from beverage companies to promotional merchandise vendors.

In this blog, we will dive into the features, benefits, and applications of printing machines, explaining why they are essential for modern businesses.

What is a Bottle Printing Machine?

A printing machine is a specialized device used to transfer images, logos, or text onto the surface of bottles. These machines use different printing techniques, such as screen printing, sublimation, or UV printing, depending on the material of the bottle and the desired finish. They are capable of printing on a variety of materials, including plastic, glass, stainless steel, and aluminum.

The machine is designed to accommodate cylindrical objects, ensuring that the print is applied evenly around the bottle’s surface. This technology is used in many industries to create custom drinkware, promotional items, and branded products.

Key Features of a Bottle Printing Machine

1. 360-Degree Printing

One of the standout features of a printing machine is its ability to print 360 degrees around the surface of the bottle. This ensures a full-wrap design without seams or gaps, providing a professional finish to the final product.

2. High-Speed Printing

Modern printing machines are equipped with high-speed technology, allowing you to print multiple bottles in a short time. This makes them perfect for businesses that need to produce large volumes of custom bottles efficiently.

3. Versatility

These machines are versatile and can print on various types of bottles, such as:

- Plastic bottles

- Glass bottles

- Aluminum bottles

- Stainless steel bottles

You can also print on different bottle shapes, including water bottles, tumblers, and even flasks, expanding the range of products you can offer.

4. Customizable Settings

Most printing machines come with customizable settings for adjusting the speed, color application, and design placement. These controls help you fine-tune the machine to meet the specific needs of each project, ensuring high-quality results every time.

5. Durable Build

Built with robust materials, printing machines are designed to withstand continuous use. They are typically made from industrial-grade components, ensuring durability and a long lifespan, even in high-demand environments.

Benefits of Using a Bottle Printing Machine

1. Create Custom Products

A printing machine allows you to create unique, custom-designed bottles that can serve as gifts, promotional items, or branded merchandise. This customization opens the door to endless design possibilities, from simple logos to complex, multi-colored graphics.

2. High-Quality Prints

These machines produce high-quality, vibrant prints that are resistant to fading, scratching, or peeling. Whether you’re using UV, sublimation, or screen printing, the machine ensures that the print adheres smoothly to the bottle surface, offering a professional, long-lasting finish.

3. Increased Production Efficiency

printing machines are designed for high-speed production, meaning you can print more bottles in less time. This increased efficiency is perfect for businesses that need to meet tight deadlines or manage large orders.

4. Cost-Effective Production

By investing in a bottle printing machine, businesses can cut down on outsourcing costs and bring their production in-house. This not only reduces printing costs but also shortens production times, making it easier to manage and fulfill orders quickly.

5. Versatility Across Industries

printing machines aren’t limited to one type of business. They can be used across various industries, including:

- Beverage companies: Print logos and branding on water bottles, wine bottles, and soft drink containers.

- Sports and fitness brands: Customize sports bottles and tumblers for teams or fitness events.

- Promotional product businesses: Create branded drinkware for companies to use as promotional gifts.

- Gift shops: Produce personalized bottles for holidays, birthdays, or special occasions.

How to Use a Bottle Printing Machine

Step 1: Prepare the Design

Start by preparing your design using design software compatible with the machine. Ensure that the design fits the dimensions of the bottle and is aligned for full-wrap printing.

Step 2: Set Up the Machine

Turn on the printing machine and adjust the settings for the specific material and design you’re using. For instance, if you’re printing on a plastic bottle, set the temperature, speed, and pressure accordingly.

Step 3: Place the Bottle in the Machine

Carefully place the bottle in the machine’s holder or clamp. Make sure it is securely positioned to avoid any misalignment during the printing process.

Step 4: Start the Printing Process

Once everything is set, start the machine. The machine will apply the design onto the bottle using heat, pressure, or UV light, depending on the printing method. Keep an eye on the process to ensure everything runs smoothly.

Step 5: Inspect the Final Product

After the printing is complete, remove the bottle from the machine and let it cool. Inspect the bottle to ensure the design was transferred correctly and that there are no flaws in the print.

Applications of the Bottle Printing Machine

printing machines have a wide range of applications in various industries

1. Promotional Products

Businesses often use custom-printed bottles as promotional items to market their brand. Branded water bottles, for example, are popular giveaways at corporate events, trade shows, and sports activities.

2. Custom Drinkware for Events

Custom drinkware is a big hit at special events like weddings, birthday parties, and sports events. Personalized bottles with names, logos, or event themes make for memorable keepsakes.

3. Branded Merchandise

Many companies sell branded bottles as part of their merchandise. Fitness centers, schools, and sports teams often create custom bottles with their logos and slogans to sell or give away to fans and members.

4. Product Labeling

printing machines can also be used in product labeling, especially for beverages. Instead of applying a separate label, the design is printed directly onto the bottle, offering a sleek, professional look.

Conclusion

A printing machine is an excellent investment for businesses looking to create custom, high-quality drinkware or promotional items. With its ability to print on various materials and bottle sizes, the machine opens up endless possibilities for customization. Whether you’re in the beverage industry, running a promotional product business, or offering personalized gifts, a printing machine will help you produce unique, vibrant designs that stand out.

Reviews

Clear filtersThere are no reviews yet.