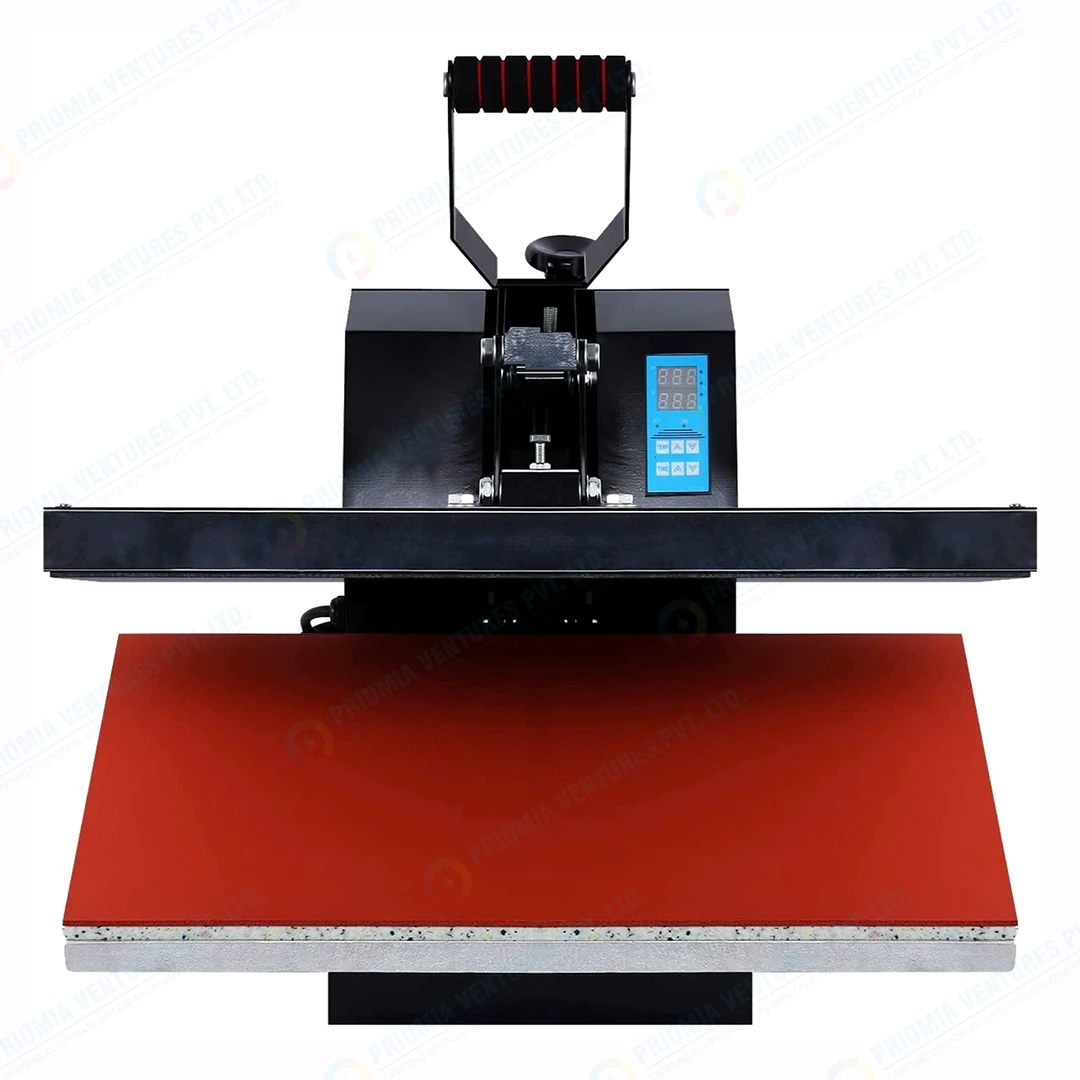

16 X 24 Sublimation Heat Press Machine

Bulk Enquiry ? Call on +91 9667 23456 8

| Brand | Priomia Ventures PVT. LTD. |

|---|---|

| Price of Single | Rs.14999/- |

| Color | Black |

| Power | 1800 W |

| Gross Weight | 25 Kgs |

| Voltage | 220v |

| Print Size | 16*24 Inch |

₹24,999.00 Original price was: ₹24,999.00.₹14,999.00Current price is: ₹14,999.00.

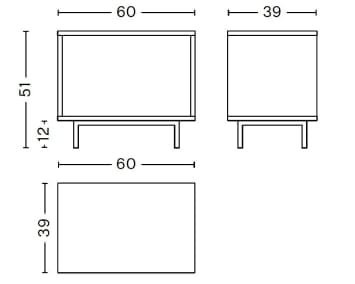

Furniture size guidelines

The compact and well-proportioned silhouette of both the seats and the small sofa, opens up to a new way of using the dining space.

A new, more intimate way of opening up new visual and proportional horizons of the living space, both in homes and in hospitality venues.

The possibility of having both the armchair and the dining and lounge small armchairs.

| Specification | Chair | Armchair | Sofas |

| Height | 37" | 42" | 42" |

| Width | 26.5" | 32.5" | 142" |

| Depth | 19.5" | 22.5" | 24.5" |

| Assembly Required | No | No | Yes |

| Packaging Type | Box | Box | Box |

| Package Weight | 55 lbs. | 64 lbs. | 180 lbs. |

| Packaging Dimensions | 27" x 26" x 39" | 45" x 35" x 24" | 46" x 142" x 25" |

Description

Sublimation Heat Press: An Essential Tool for Customization

16 X 24 Sublimation Heat Press Machine have become an indispensable tool for creating custom designs on a variety of materials. From t-shirts and mugs to phone cases and mouse pads, these machines provide a convenient way to personalize items with vibrant, long-lasting prints. Let’s explore the benefits and features of sublimation heat press machines.

1. Versatility in Customization 16 X 24 Sublimation Heat Press Machine offer incredible versatility. They can transfer designs onto various substrates such as fabrics, ceramics, metals, and plastics. This makes them ideal for personalizing gifts, creating branded merchandise, and producing custom apparel.

2. High-Quality Prints One of the standout features of 16 X 24 Sublimation Heat Press Machine is the quality of prints they produce. The sublimation process uses heat to transfer ink onto the desired material, resulting in bright, vivid colors that are resistant to fading, peeling, or cracking.

3. Efficient and Time-Saving Sublimation heat pres machines are designed for efficiency. Once you have your design ready, the heat press transfers it onto the material quickly and accurately. This makes it possible to produce multiple custom items in a short amount of time, boosting productivity.

4. Ease of Use Operating a sublimation heat pres machine is straightforward. With a digital control panel, users can easily adjust the temperature, pressure, and time settings to achieve the perfect transfer. This user-friendly design makes it accessible to both beginners and experienced professionals.

5. Cost-Effective Customization For businesses and hobbyists alike, sublimation heat press machines offer a cost-effective way to create custom products. By investing in a heat press machine and sublimation supplies, you can produce unique items at a fraction of the cost compared to outsourcing.

6. Diverse Applications Sublimation heat press machines are suitable for a wide range of applications. Whether you’re creating personalized gifts for special occasions or designing custom apparel for your brand, these machines provide the flexibility to bring your creative vision to life.

Tips for Using a Sublimation Heat Press

If you’re new to sublimation or looking to enhance your results, here are some tips for using a sublimation heat pres effectively:

- Prepare Your Design Properly: Ensure your design is ready for sublimation by using compatible inks and printing on the correct type of paper. Mirror your design before printing so it appears correctly when transferred.

- Choose the Right Temperature and Time: Different materials require different heat settings. Refer to the manufacturer’s guidelines for optimal temperature and time settings for each type of substrate.

- Apply Even Pressure: Consistent pressure is key to a successful transfer. Make sure the heat press applies even pressure across the entire design area to avoid uneven prints.

- Use Heat-Resistant Tape: Secure your design to the substrate using heat-resistant tape to prevent shifting during the transfer process.

- Protect Your Heat Press: Use a protective layer such as parchment paper or a Teflon sheet between the heat press and your substrate to prevent ink from transferring onto the press.

- Maintain Your Equipment: Keep your heat pres clean and in good working condition. Regular maintenance, such as cleaning the platen and checking for wear and tear, can prolong the life of your machine.

Innovative Ideas with Sublimation Heat Press

Sublimation heat press machines open up a world of creative possibilities. Here are some innovative ideas to try:

- Create Matching Sets: Design matching t-shirts, hats, and tote bags for events, teams, or family gatherings.

- Personalize Gifts: Add personal touches to gifts such as custom photo frames, coasters, or puzzles.

- Decorate Home Accessories: Transform plain home decor items like cushions, tablecloths, and curtains with custom prints.

- Design Custom Apparel: Produce unique clothing lines with custom designs, logos, or artwork.

- Offer Customization Services: Start a small business offering custom design and printing services for individuals and businesses.

Final Thoughts

Sublimation heat press machines provide a simple and efficient way to create personalized products. By understanding how to use the machine effectively and exploring innovative applications, you can unlock the full potential of sublimation for both personal and professional projects. Whether you’re creating custom gifts or building a business around customization, a sublimation heat press is an essential tool for bringing your ideas to life.

Reviews

Clear filtersThere are no reviews yet.